Woodworkers know that at some point you have to start making spoons. It is a good way to experiment with different techniques and tools. Some people make nothing but spoons of different shapes and sizes. However, I don‘t have skills to do anything as impressive as these people do and so I decided to make a very simple pare of spoons using nothing, but a piece of paper, some tape, a tiny lathe and a couple of chisels. This is how they were made.

I know a couple of questions have to be answered at the very beginning. The lathe is called CNC007 Mini Lathe Beads Machine. There are several versions of the same thing in different Chinese online stores, snoop around and you will find something. It is a good toy for people, who want to woodturn in their living room (not even joking) or move a lot, or for children, or for model making. Not a substitute for a real lathe, I know. The gauge is made by Norex, wood is black alder.

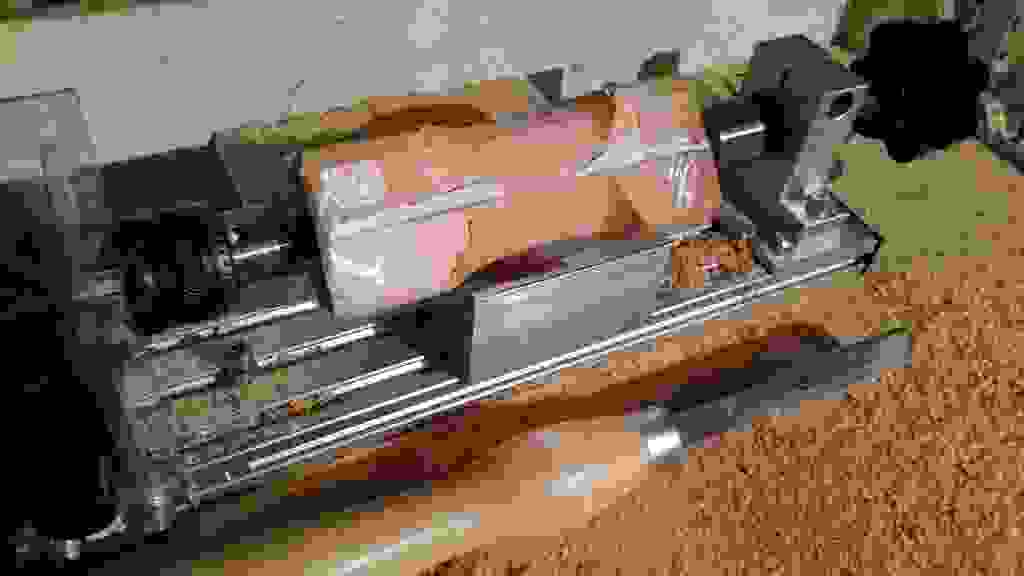

So I got this idea I can woodturn a couple of spoons my tiny lathe with some wood that I had laying around. I saw somewhere online that glueing two pieces of wood together with paper in between allows for quick separation, but holds well enough while turning. So that’s what I did – I glued a couple of 14 cm long pieces of alder together with a piece of normal paper in between. I left it to dry for a couple of days (several hours would’ve been enough) and then put the blank on the lathe.

Now on a normal lathe you would likely have a proper 4-jaw chuck, which would hold a square-is blank very nicely. However, my lathe is so small I have to turn between centres. Live tailstock is also shaped like a cone. This combination got me a little worried that the piece will fall apart as both ends get wedges on a relatively weak glue-and-paper line. So I put some regular packing tape on both ends for my psychological comfort more than anything.

Lathe took asymmetrical piece rather well. There were some vibrations, but nothing dramatic and the tiny motor was spinning just fine. At first I rounded the centre between pieces of tape just to remove some mass. And then I got enough courage to make the entire piece round. It didn’t take too long and everything went very safely. At this point I had to start looking for the shape of my spoons. I knew from the very beginning it is going to be like turning a log to a toothpick, but that gave me a lot of room to see what I would like these spoons to be.

Of course, as I turned off most of the glue surface, pieces started coming apart – that was inevitable as the tailstock was wedging itself in.

However, I continued turning. Since pieces were small, I wasn’t so worried that they will fly apart and hit me to the face. I decided to go with a relatively deep, almost scoop-sized bowl, sweeping handle and a couple of decorative beads at the end.

However, I did manage to finish turning and do all the sanding on the lathe. Since pieces were small, I wasn’t so worried that they will fly apart and hit me to the face. Then I pulled it off the lathe, separated the pieces, cut off that little piece left on the drive end and sanded it to shape. By the way, paper trick worked magically, but you already know that since pieces were coming apart on the lathe already.

I sanded the paper off, but didn’t do anything else on that side. I decided to leave spoons on my desk until I have a carving chisel to hollow them out. But working get boring sometimes and I had this very sharp 2 mm straight chisel laying around so I started playing with it and in no time at all I hollowed out the spoons.

Obviously, that is not the way to do that and I didn’t plan this, but it just happened this way. If you are planning a similar project, I strongly advise you to buy proper tools, secure your work and not to get your hands in a way of a sharp edge.

Anyway, I sanded the inside surfaces to 600 grit sandpaper, because that is what I finished the outside with on the lathe. And this is the end product. Mind you, I could have sanded it better and using a proper carving gauge would’ve resulted in less deep grooves that did not want to sand away.

Nothing to be proud of, but I am glad I did it. Except the paper trick, all the ideas and techniques I came up with by myself as I was working along. This was the third thing I’ve ever turned and it turned out quite well. I already know a couple of other projects I am going to turn on this lathe and one of them is going to involve hollowing out a form on a lathe. So look forward to that.