“You’re like a train with paper wheels” – this sounds like an insult, doesn’t it? However, train wheels made from paper actually existed and were regarded as a highly advanced innovation.

Train wheels are made of steel, which is strong, durable and a relatively cheap metal. However, back in the 19th century when railroads were bumpy and train cars had little to no suspension, this metal-on-metal action made for a noisy and uncomfortable journey. Richard N. Allen, an American locomotive engineer, came up with a solution – wheels should be made of a material that absorbs vibrations very well. That material somehow was paper. In 1867, Allen already had a company that manufactured paper from straw and later used that paper to make train wheels.

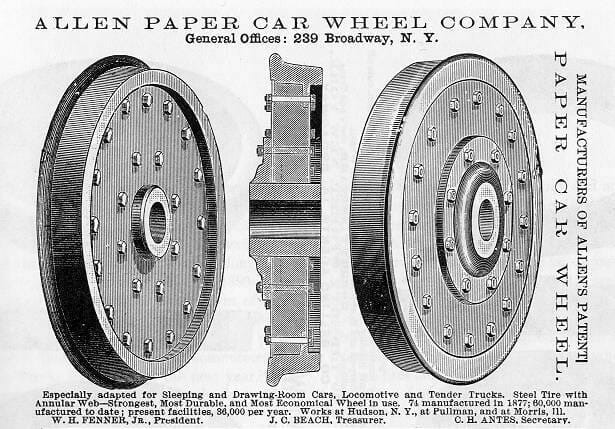

A huge heavy train on paper wheels sound like a bad idea? Well, those wheels weren’t just some school-grade paper. The Allen Paper Car Wheel Works produced composite steel (or iron) and paper wheels.

At first a machine punched out huge paper disks. They were then laminated together using simple flour-based glue – it was like a papier–mâché project. Paper sandwiches were joined together until a 200-sheet-thick disc was created. It was then compressed with a 650 tonne hydraulic press. This paper composite material was then dried for 6-8 weeks and turned on a lathe to make it round and true.

The paper disc was then sandwiched between two metal discs that allowed the wheel to be attached to the railroad car chassis. The edge of the wheel was covered by a thick metal ring, which was the actual contact surface – paper never directly touched either the wagon chassis or the rails.

It’s been proven that these paper-filled wheels were actually excellent at absorbing vibrations and damping the noise. Richard Allen’s company, based in New York, soon began receiving large orders. In 1871, Pullman, manufacturer of luxury railway cars, ordered 100 of such paper wheels, which were fitted on sleeping and dining cars. Allen’s company grew quickly and in 1881 paper wheels were being produced in New York and Chicago. One workshop with around 80 employees produced around 24 paper composite wheels per day. In 1886, it was announced that 60,000 of Allen’s paper wheels were already in use globally and this number was quickly growing.

Allen’s paper wheels were later produced in the United Kingdom, the idea reached Germany as well. Of course, in the US, where long train journeys were very popular, paper wheels were in greatest demand. And they actually worked.

As silly as the idea may seem to you, Richard Allen’s paper wheels did what they were designed to do – they absorbed vibrations and made trains quieter and more comfortable. But, as you may have noticed, paper wheels are not used anymore.

In fact, paper wheels were banned as early as 1915. After several accidents, it was decided that paper composite wheels are not safe. The problem was that they fell apart very suddenly. Steel wheels normally wear down slowly and specialists can tell when they need to be replaced. Meanwhile paper wheels simply gave up without showing any serious signs of wear, because they fell apart from the inside. The longevity of paper-core wheels was not just bad – it was unpredictable.

The 1915 ban ended the production of paper wheels. And later, with the improvement of the design of both trains and railways, they were no longer needed.